Lihlahisoa

Perforated steel strip PE pipe Bakeng sa phepelo ea metsi

Kopo

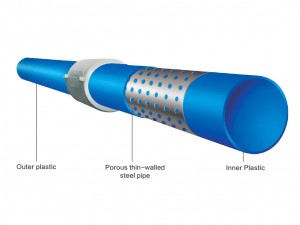

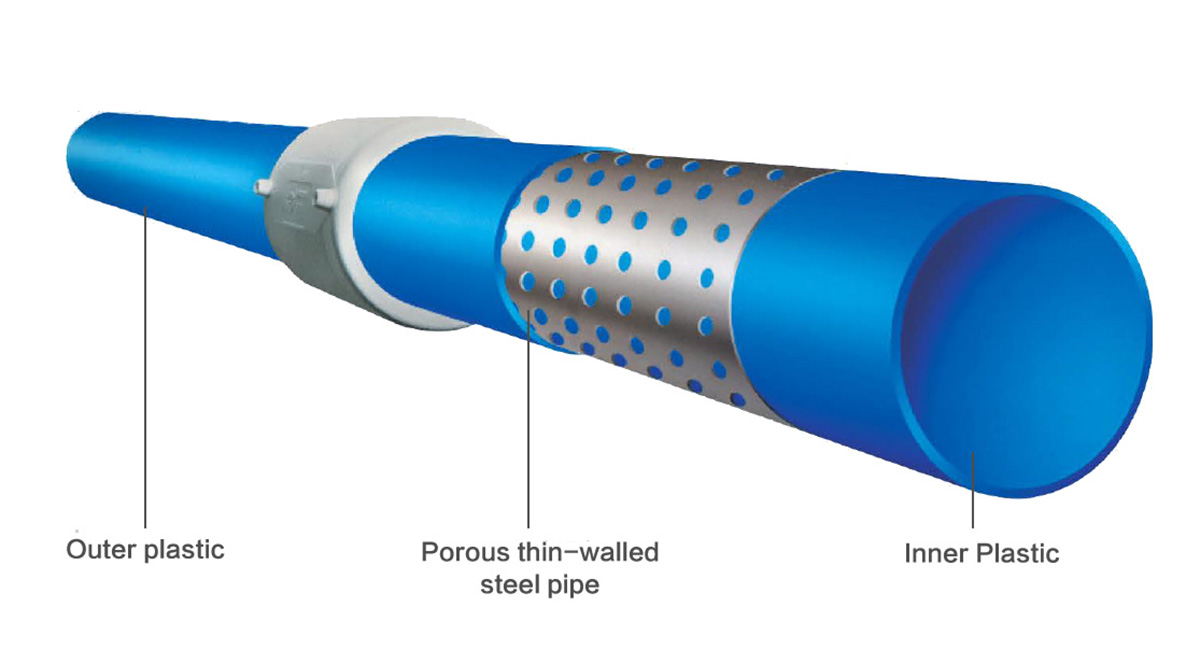

Peipi e entsoeng ka tšepe e entsoeng ka tšepe ea polyethylene e entsoe ka tšepe e pholileng le thermoplastic e le lisebelisoa tse tala, 'me liphaephe tsa tšepe tse nang le porous tse tšesaane tse entsoeng ke argon arc butt welding kapa plasma spiral welding li sebelisoa e le li-reinforcements. Mekhahlelo e ka ntle le e ka hare ke thermoplastic e nang le mahlakore a mabeli. Mofuta o mocha oa phaephe ea khatello ea motsoako, Hobane sekontiri sa tšepe se nang le marako a masesaane se phuthetsoe ka thermoplastic e tsoelang pele, phala ena e kopantsoeng ha e hlōle feela mefokolo ea liphaephe tsa tšepe le liphaephe tsa polasetiki, empa hape e na le ho tiea ha lipeipi tsa tšepe le ho bola. ho hanyetsa liphaephe tsa polasetiki. Ke tharollo bakeng sa liindasteri tsa petroleum le lik'hemik'hale. Ke phaephe e hlokahalang ka potlako ea liphaephe tse tiileng tse kholo le tse mahareng tse thata masimong a meriana, lijo, merafo, khase le masimo a mang. Hape ke katleho ea phetoho ea thekenoloji ho rarolla lipeipi tse kholo tsa kaho le phepelo ea metsi ea masepala. Ke mofuta o mocha oa lipeipi tse kopaneng ho 21stlekholo la lilemo.

Likaroloana

Matla a phahameng le katoloso e tlase ea mola.

Ka lebaka la matlafatso ea foreime ea tšepe, peipi e entsoeng ka tšepe e entsoeng ka perforated e na le matla a phahameng, e tsitsitseng le ho hanyetsa ho feta phala ea polasetiki. Ka nako e ts'oanang, phello ea thibelo ea foreimi ea tšepe e boetse e etsa hore peipi e entsoeng ka tšepe e entsoeng ka perforated e be le mohala o tlaase o tšoanang le oa pipe ea tšepe. Katoloso coefficient le сгеер khanyetso.

Corrosion and wear resistance.

Thepa e phahameng ea polyethylene e khethiloe bakeng sa peipi e entsoeng ka tšepe ea perforated ea polasetiki ke а crystalline non-polar polymer material e nang le thepa e tsitsitseng ea lik'hemik'hale, ho hanyetsa boholo ba acid, letsoai la alkali le mecha ea litaba ea manyolo, le polase ea electrochemical. Ts'ebetso ea ho sila e phahame ka makhetlo a 5 ho feta ea liphaephe tsa tšepe.

Tekheniki Parameters

Sehlahisoa sena se sebelisa resin e khethehileng ea polyethylene, 'me thepa ea eona ea' mele le ea mechine e kopana le Lekala la kaho le maemo a CJ/T181-2003 le maemo a indasteri ea lik'hemik'hale HG/T3706-2014.

| Tlhaloso ea boholo, ho kheloha le khatello ea lebitso: kopana le litlhoko tsa Lekala la kaho maemo a CJ/T181-2003 | |||||

| Bophara ba ka ntle ka lebitso le ho kheloha | Botenya ba lebota ka lebitso le ho kheloha | Ho tsoa ho pota | Khatello ea lebitso | Bonyane ba boleng ba S | Bolelele le ho kgeloha |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 2.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 2.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 2.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 2.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 2.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.6 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.6 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.6 | 2.5 | |

| 225+1.4 0 | 11.5+2.4 0 | 4.5 | 1.6 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 1.6 | 3.5 | |

| 280+1.5 0 | 12.5+2.6 0 | 5.6 | 1.6 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 1.25 | 3.5 | |

| 355+1.6 0 | 14.0+2.8 0 | 7.1 | 1.25 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 1.25 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 1.0 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 1.0 | 4.0 | |

| Tlhokomeliso: Khatello ea lebitso la pipe e kopantsoeng ke khatello e phahameng e lumelletsoeng hore pipe e tsamaise metsi ka 20 ° С. Haeba mocheso o fetoha, khatello ea ho sebetsa e lokela ho lokisoa ho ea ka mocheso oa mocheso oa mocheso oa thepa e fapaneng. S value: sebaka se ka thōko ho bophara ba ka ntle ba ho matlafatsa ho ea karolong e ka ntle ea phala. | |||||

| Litlhoko tsa ts'ebetso ea 'mele le ea mochini | ||

| Morero | Tshebetso | |

| Ho satalla ha lesale, KN/m2 | >8 | |

| Tlhahlobo e bataletseng | Ha e robehe | |

| Ho fokotseha ha longitudinal (100 ° С, boloka 1h) | <0.3% | |

| Teko ea Hydraulic | Mocheso: 20 ° С; Nako: 1h; Khatello ea lebitso x2 | Ha e robehe |

| Mocheso: 80 ° С; Nako: 165h; Khatello: Khatello ea lebitso x2x0.71 (fokotso ntlha) | ||

| Teko ea khatello ea ho phatloha | Mocheso: 20 ° С, khatello ea ho phatloha ≥ khatello ea lebitso x3.0 | Ho qhoma |

| Nako ea ho kenya oxidation (200 ° С), min | ≥20 | |

| *Ho hanyetsa boemo ba leholimo* Kamohelo e akaretsang ea lipeipi≥3.5J/m2 Ka mor'a ho tsofala matla | Teko ea Hydraulic, maemo a liteko a tšoana le ntlha ea 3 tafoleng ena | Ha e robehe |

| Teko ea khatello ea ho phatloha, maemo a teko a tšoana le ntlha ea 4 tafoleng ena | Eseng ho phatloha | |

| Nako ea ho kenya oxidation (200 ° С), min | ≥10 | |

*Ke feela bakeng sa peipi e kopaneng e putsoa*