Lihlahisoa

Perforated tšepe hlobolisa PE pipe Bakeng sa ho thibela mocheso

Kopo

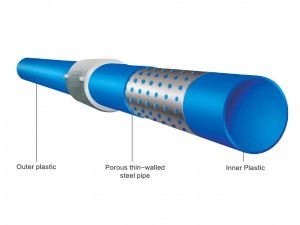

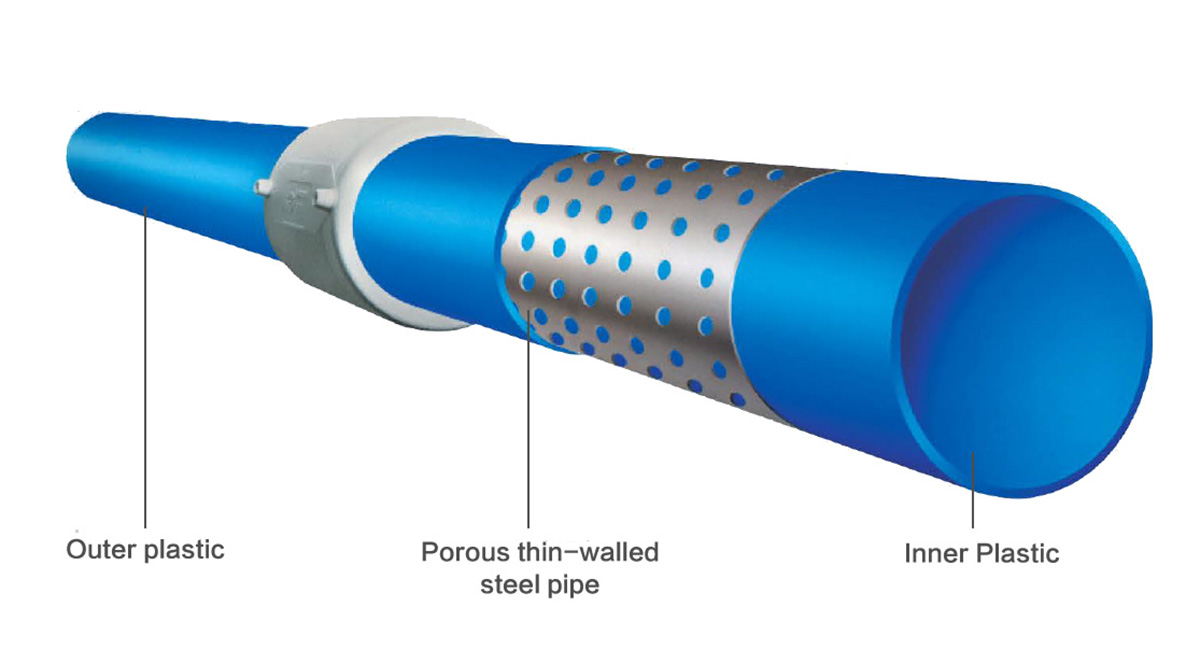

Peipi e entsoeng ka tšepe e entsoeng ka tšepe ea polyethylene e entsoe ka tšepe e pholileng le thermoplastic e le lisebelisoa tse tala, 'me liphaephe tsa tšepe tse nang le porous tse tšesaane tse entsoeng ke argon arc butt welding kapa plasma spiral welding li sebelisoa e le li-reinforcements. Mekhahlelo e ka ntle le e ka hare ke thermoplastic e nang le mahlakore a mabeli. Mofuta o mocha oa phaephe ea khatello ea motsoako, Hobane sekontiri sa tšepe se nang le marako a masesaane se phuthetsoe ka thermoplastic e tsoelang pele, phala ena e kopantsoeng ha e hlōle feela mefokolo ea liphaephe tsa tšepe le liphaephe tsa polasetiki, empa hape e na le ho tiea ha lipeipi tsa tšepe le ho bola. ho hanyetsa liphaephe tsa polasetiki. Ke tharollo bakeng sa liindasteri tsa petroleum le lik'hemik'hale. Ke phaephe e hlokahalang ka potlako ea liphaephe tse tiileng tse kholo le tse mahareng tse thata masimong a meriana, lijo, merafo, khase le masimo a mang. Hape ke katleho ea phetoho ea thekenoloji ho rarolla lipeipi tse kholo tsa kaho le phepelo ea metsi ea masepala. Ke mofuta o mocha oa lipeipi tse kopaneng ho 21stlekholo la lilemo.

Likaroloana

Boima ba lesale bo phahameng le ho tiea ho hoholo

Peipi e entsoeng ka tšepe e entsoeng ka tšepe e nang le perforated e na le ho satalla ho phahameng le ho tiea ho hoholo haufi le lipeipi tsa tšepe, 'me e loketse ka ho khetheha bakeng sa ho beha liphasejeng tsa liphaephe.

Ts'ebetso ea polokeho

Foreimi e matlafalitsoeng ea peipi e kopantsoeng ea lebanta la polasetiki e nang le perforated le lisebelisoa tse tala tsa polasetiki li kentsoe ka botlalo ka letlooa le nang le maqhubu, 'me ho na le matšoenyeho a ho ebola polasetiki ea lebota le kahare le kantle le foreimi ea tšepe. Khokahano ea fusion ea motlakase e na le khanyetso e matla ho setšoantšo sa axial, mme sistimi ea liphaephe e na le ts'epo e phahameng. Tlas'a maemo a tloaelehileng, bophelo ba tšebeletso bo ka fihla lilemo tse 50.

Tekheniki Parameters

| Bophara ba ka ntle ka lebitso le ho kheloha | Botenya ba lebota ka lebitso le ho kheloha | Khatello ea lebitso | Bonyane ba boleng ba S |

| Dn(mm) | En(mm) | Mpa | Mm |

| 50+0.5 0 | 6.0+1.5 9 | 2.0 | 1.5 |

| 63+0.6 0 | 6.5+1.5 0 | 2.0 | 1.5 |

| 75+0.7 0 | 7.0+1.5 0 | 2.0 | 1.5 |

| 90+0.9 0 | 8.0+1.5 0 | 2.0 | 1.5 |

| 110+1.0 0 | 9.0+1.5 0 | 2.0 | 1.5 |

| 140+1.1 0 | 9.0+1.5 0 | 1.6 | 2.0 |

| 160+1.2 0 | 10.0+1.8 0 | 1.6 | 2.0 |

| 200+1.3 0 | 11.0+2.0 0 | 1.6 | 2.0 |

| 225+1.4 0 | 11.5+2.2 0 | 1.6 | 2.0 |

| 250+1.4 0 | 12.0+2.2 0 | 1.6 | 2.0 |

| 280+1.5 0 | 12.5+2.3 0 | 1.6 | 2.5 |

| 315+1.5 0 | 13.0+2.5 0 | 1.25 | 2.5 |

| 355+1.6 0 | 14.0+2.5 0 | 1.25 | 2.5 |

| 400+1.6 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 450+1.8 0 | 15.0+2.8 0 | 1.25 | 2.5 |

| 500+2.0 0 | 16.0+3.0 0 | 1.25 | 2.5 |

| Lintho tsa 'mele tsa phala e kopantsoeng | ||

| Morero | Tlhokahalo ea ts'ebetso | |

| Ho senya botsitso tlas'a khatello | Ha ho mapetsong | |

| Sekhahla sa ho fokotseha ha longitudinal (110 ° С, boloka 1h) | <0.3% | |

| Teko ea Hydraulic | Mocheso: 20 ° С; Nako: 1h; Khatello: khatello ea lebitso x1.5 | Ha e robehe Ha ho dutla |

| Mocheso: 70 ° С; Nako: 165h; Khatello: Khatello ea lebitso x1.5x0.76 | ||

| Mocheso: 85 ° С; Nako: 165h; Khatello ea ho phatloha ≥ khatello ea lebitso x1.5x0.66 | ||