Lihlahisoa

Perforated tšepe hlobolisa PE pipe Bakeng sa khase

Kopo

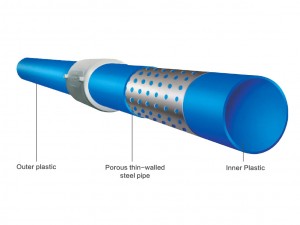

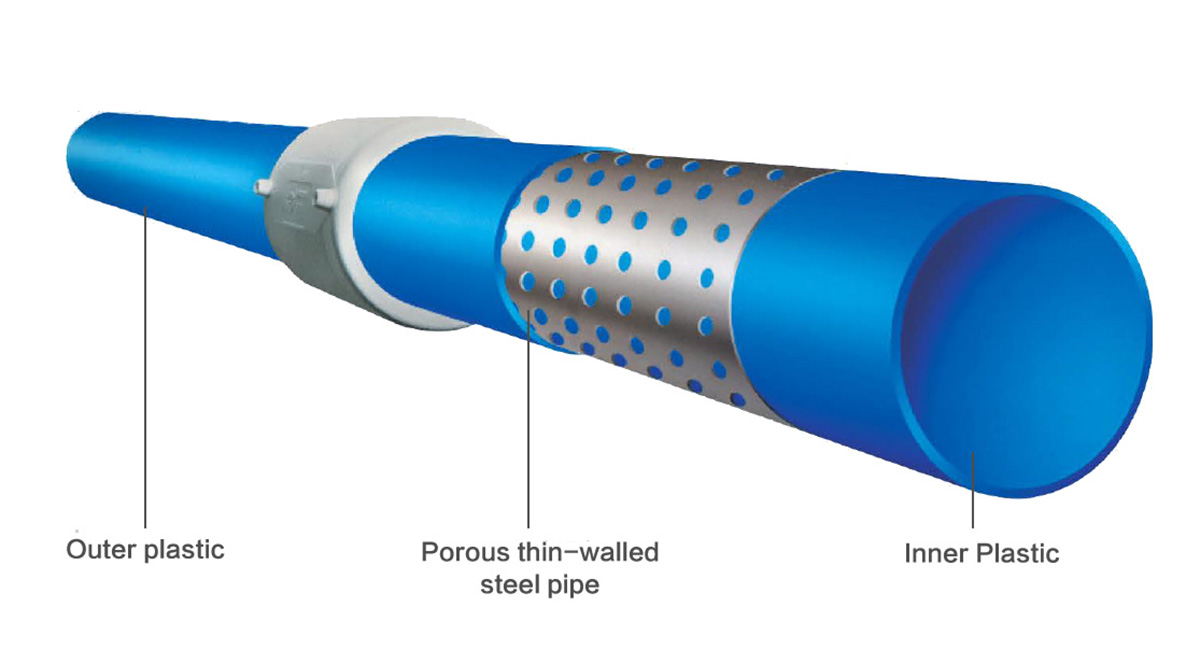

Peipi e entsoeng ka tšepe e entsoeng ka tšepe ea polyethylene e entsoe ka tšepe e pholileng le thermoplastic e le lisebelisoa tse tala, 'me liphaephe tsa tšepe tse nang le porous tse tšesaane tse entsoeng ke argon arc butt welding kapa plasma spiral welding li sebelisoa e le li-reinforcements. Mekhahlelo e ka ntle le e ka hare ke thermoplastic e nang le mahlakore a mabeli. Mofuta o mocha oa phaephe ea khatello ea motsoako, Hobane sekontiri sa tšepe se nang le marako a masesaane se phuthetsoe ka thermoplastic e tsoelang pele, phala ena e kopantsoeng ha e hlōle feela mefokolo ea liphaephe tsa tšepe le liphaephe tsa polasetiki, empa hape e na le ho tiea ha lipeipi tsa tšepe le ho bola. ho hanyetsa liphaephe tsa polasetiki. Ke tharollo bakeng sa liindasteri tsa petroleum le lik'hemik'hale. Ke phaephe e hlokahalang ka potlako ea liphaephe tse tiileng tse kholo le tse mahareng tse thata masimong a meriana, lijo, merafo, khase le masimo a mang. Hape ke katleho ea phetoho ea thekenoloji ho rarolla lipeipi tse kholo tsa kaho le phepelo ea metsi ea masepala. Ke mofuta o mocha oa lipeipi tse kopaneng ho 21stlekholo la lilemo.

Likaroloana

Ts'ebetso ea bohloeki

Lenane la bohloeki le polokeho ea phala e entsoeng ka tšepe e entsoeng ka tšepe e entsoeng ka perforated e finyella litlhoko tsa GB9687 "Hygienic Standards for Polyethylene Molded Products for Food Packaging" le GВ/Т17219 "Tekanyetso ea Tekanyetso ea Tšireletseho bakeng sa Thepa ea Kabo ea Metsi a Nooang le ka Lisebelisoa le Lisebelisoa tsa Tšireletso". Ke eona e nkang sebaka se setle ka ho fetisisa bakeng sa phala ea masenke le phala ea tšepe.

Lerako le ka hare le boreleli le ts'ebetso ea ho potoloha

Lerako le ka hare la phala e entsoeng ka tšepe ea tšepe e entsoeng ka tšepe e boreleli haholo, 'me ho ba thata ka ho feletseng ke 1/20 feela ea phala ea tšepe. Matla a ho tsamaisa tlas'a maemo a tšoanang a ka bang 30% ho feta a pipe ea tšepe.

Tekheniki Parameters

| Tlhaloso ea boholo, ho kheloha le khatello ea lebitso: kopana le litlhoko tsa Lekala la kaho maemo a CJ/T181-2003 | |||||

| Bophara ba ka ntle ka lebitso le ho kheloha | Botenya ba lebota ka lebitso le ho kheloha | Ho tsoa ho pota | Khatello ea lebitso | Bonyane ba boleng ba S | Bolelele le ho kgeloha |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 0.6 | 4.0 | |

| Tlhokomeliso: Khatello ea lebitso la pipe e kopantsoeng ke khatello e phahameng e lumelletsoeng hore pipe e tsamaise metsi ka 20 ° С. Haeba mocheso o fetoha, khatello ea ho sebetsa e lokela ho lokisoa ho ea ka mocheso oa mocheso oa mocheso oa thepa e fapaneng. S value: sebaka se ka thōko ho bophara ba ka ntle ba ho matlafatsa ho ea karolong e ka ntle ea phala. | |||||

| Litlhoko tsa ts'ebetso ea 'mele le ea mochini | ||

| Morero | Tshebetso | |

| Ho satalla ha lesale, KN/m2 | >8 | |

| Ho fokotseha ha longitudinal (110 ° С, boloka 1h) | <0.3% | |

| Teko ea Hydraulic | Mocheso: 20 ° С; Nako: 1h; Khatello ea lebitso x2 | Ha e robehe |

| Mocheso: 80 ° С; Nako: 165h; Khatello: Khatello ea lebitso x2x0.71 (fokotso ntlha) | ||

| Teko ea khatello ea ho phatloha | Mocheso: 20 ° С, khatello e phatlohileng≥khatello ea lebitso x3.0 | Ho qhoma |

| Nako ea ho kenya oxidation (200 ° С), min | >20 | |

| E hanana le keketseho e potlakileng ea khatello ea maikutlo (80°С, 4.0Mpa)/h | >1000 | |

| Ho hanyetsa boemo ba leholimo (ka mor'a hore phala e fumane≥3.5GJ/m2matla a ho tsofala) | Kopana le litlhoko tsa lintho tsa 2,3 le 4 tafoleng ena, 'me li ka boloka ts'ebetso e ntle ea welding | |